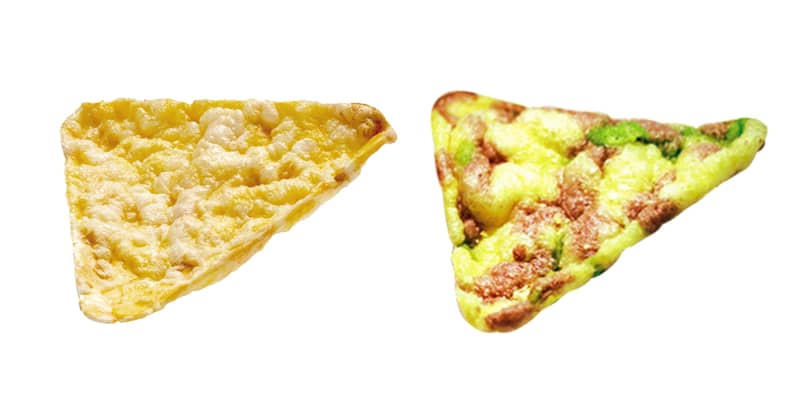

Machines for cakes and non-fried snacks

Fast working cycle

Green Puff has an average working cycle around 9”

Low maintenance

The simple constructive concept and the solidity of the machine drastically reduce maintenance cost and machine stops, increasing operational hours and of course efficiency

Quick operations

Quick replacement of dosing plate (less than 1 minute)

Movable structure

Thanks to the 4 pivoting wheels, Green Puff can be placed and moved without using the forklift

Complete shell with protective panels

The shell helps steam and fumes to be directed into the suction hood avoiding the possibility of dispersion in the workplace air. Green Puff can also be provided with lower drawer to collect production waste

Green technology

The machine works with compressed air and electricity, without using mineral oils

Technical Features

Green Puff is composed by 2 independent presses, powered by compressed air and electricity, which are placed on a structure with pivoting wheels.

All the movements of the machine are pneumatic and ensure the necessary power to expand a lot of variety of cereals and/or pellet with a high expansion quality and texture.

The material used for the forming mold is the tempered steel, coated with titanium nitride (TIN or Tinite), in order to ensure a long life and to reduce fouling during production. The molds, as all the other parts which are in contact with food, are realized with food-grade certified materials.

The heating of the molds is carried out using special heaters and temperature is controlled through to a PLC. On request we can install separate temperature regulators. Each machine, composed by 2 independent presses, is managed by a PLC. From the touch control panel you can set all the working parameters, save the recipes, check cycle data and warnings thanks to an efficient diagnostic system.

Suitable cereals: whole corn or grits, rice, brown rice, spelt, wheat, barley, pellet, pulses and many others.

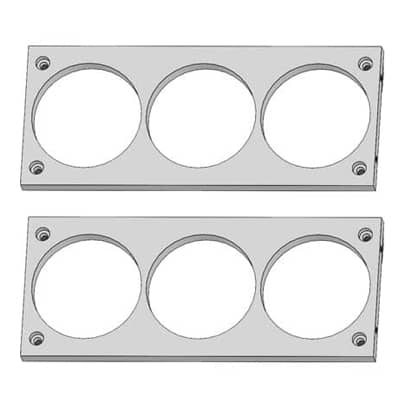

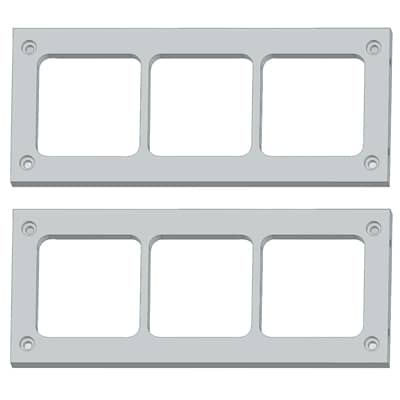

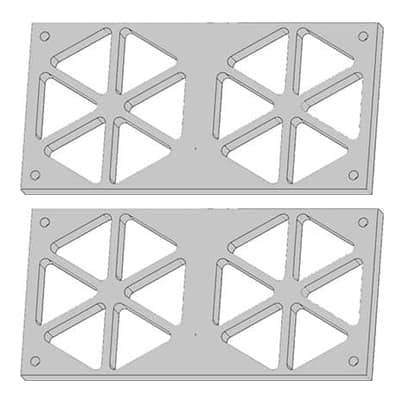

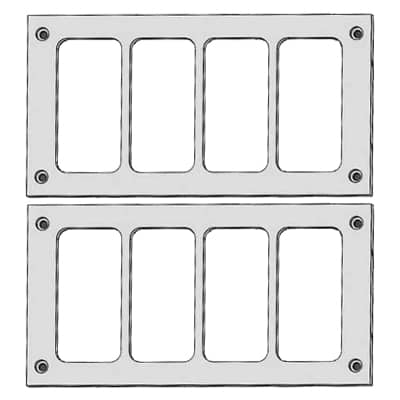

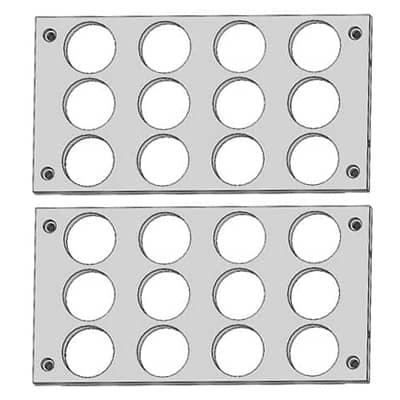

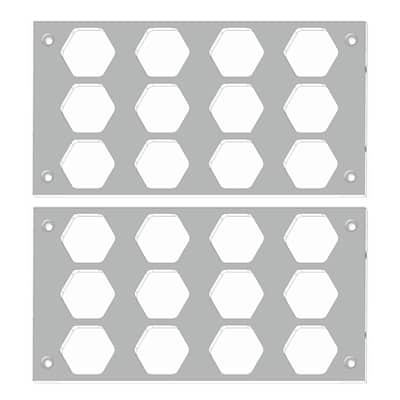

molds

Shape: Ø 90 mm

Cakes/cycle: 6 (4 - 10 g)

Capacity: up to 2700 pcs/hr

Shape: 80x80 mm

Cakes/cycle: 6 (4 - 10 g)

Capacity: up to 2700 pcs/hr

Shape: 53x53x53 mm

Cakes/cycle: 24 (0,8 -1,3 g)

Capacity: up to 10800 pcs/hr

Shape: 110x55 mm

Cakes/cycle: 8 (4 - 10 g)

Capacity: up to 3600 pcs/hr

Shape: Ø 40 - 45 mm

Cakes/cycle: 24 (0,8 - 2 g)

Capacity: up to 10800 pcs/hr

Shape: Ø 48 mm

Cakes/cycle: 24 (0,8 -2 g)

Capacity: up to 10800 pcs/hr